Once the thermostat choosen, the next move was to see how to interconnect the Raspberry Pi and the Z-Wave network.

USB Sticks

After investigation, it appears that there are 2 possibilities by 3 main manufacturers:

- USB Sticks with SigmaDesigns SDK (the company behind Z-Wave). Compatible with Z-Wave plus.

- USB Sticks with a inclusion button by Aeotec (Z-Stick S2)

- USB Sticks running Z-Way by Z-Wave>me (ZStick)

The other possibility, still by Z-Wave>me is called the Razberry and is an add-on for the Raspberry Pi. Cool... but not really future-proof.

The solutions by Z-Wave>me seem to use a specific software called Z-Way and running in Javascript. Unfortunately, the documentation is very scarce and in the end I went for the Stick compatible with Z-Wave plus.

Openzwave

As I mentionned before, Z-Wave is a very closed world, at the opposite end of Open Source. Fortunately, reverse engineering was done and there is a Z-Wave free software library called Openzwave. There is even a Python wrapper!

First tries

If the compilation part takes ages, it is totally painless. But all first attempts were failures and I couldn't understand what was going on... Even using the control panel. Associating 2 of the elements (Thermostat, actuator, static controller) was fine but all three together didn't work as I expected. Even following the numerous recipes found on the forums.

Then I found a way which works for me:

- Reset/Exclude everything.

- Include the Actuator on the Thermostat (back to the way the pack was when delivered).

- Set the RaspberryPi/Stick in "ReceiveConfiguration" mode.

- On the SCS317: Setup/Set up Z-Wave/Controller Shift to promote the Raspberry as the Primary Controller.

After this, the all 3 elements are connected:

- Node #1: Thermostat SCS317

- Node #2: Actuator SSR303

- Node #3: Raspberry Pi/Stick (Primary)

Now, what can I do?

Z-Wave learning curve is rather steep and badly documented (because of the NDA).

Another particularity is that almost everything is asynchronous... and very slow. Especially when it comes to the SSC317. In order to minimise the battery usage, operation can wait for... hours!

Other example, on the Control Panel, things can take several minutes before one received a response. Not talking about the state of the network which most of the time doesn't seem to reach the "Ready" level! :-(

Frustrations

Well, the thermostat is recognised by openzwave but half the interesting functions are not (yet) implemented. It looks like if openzwave was mainly developed for switches and relays. Sadly enough, anything around the schedule commands (0x53) are not taken into account so there is, at the moment, no way to read/write the 7-day programme.

I wasn't able to read either the current temperature set point (which is odd because it should work).

After playing a bit, I decided that Z-Wave is not yet totally fonctional without a proper certified box. I'm still wondering what the implementation of Z-Way is like and if it is more advanced than openzwave.

Usages

The values I can access to are:

- Status of the switch on the actuator (on/off).

- Status of the thermostat (Heat/Idle). In theory the same as above.

- Current temperature of the room (when changing).

- Thermostat battery power

- A few other random values and versions...

For the moment, I shelved idea of overriding the On/Off of the heating remotely (but this works fine). Since I want to use Python3 for the main software and this project is in Python (or C++), the simplest set-up was to have both running separately.

One process is responsible for the z-wave management. Every 5 minutes, a refresh of value is requested (will be honoured... or not) and a few second later, a JSON value file will be dumped.

The main process can then read this JSON file and do what it wants with the values (mainly sending them to RRD).

I'll re-evaluate my options at a later stage.

Last year, following an article from raspberrypi.org's Blog I decided to support the project of these teenagers and pre-order a kit on Tindie.

A few months later, I indeed received the board (v1.2) and the sensors. In the meantime, the design had changed (some of the sensors too) and if everything works, the lack of calibration on analogue sensors make them almost useless.

Code is sometimes a bit messy (actually a sort of mashup from Adafruit examples), and two things are surprising on this project: The active main loop (without sleep) which mean that the microcontroller is busy 100% (hence becomes hot) and the fact the temperature sensor is bang above it!

But hey, I should have investigated more before and after all it got me started thus I can't really complain.

So I decided the use the card but aside from main board. It will be outside the box and linked by a ribbon cable.

Sensors installed on the Airpi board

BMP085

- Temperature + Pressure

- I²C

DHT22

- Temperature (unused) + Humidity

- Specific 1-wire protocol

LDR

- Light sensor

- Via the ADC MCP3008

Microphone

- Noise

- Via MCP6283 (op-amp) and ADC MCP3008

MiCS-2710

- Nitrogen Dioxide (NO2)

- Via the ADC MCP3008

- Datasheet

MiCS-5525

- Carbon Monoxide (CO)

- Via the ADC MCP3008

- Datasheet

Python 3

The main sections were rewritten to Python 3. For example, py-smbus for which I found a patch on a forum or Adafruit DHT.

RRD

Once again, data will be stored using RRD.

Main difference with gas and electricity readings is the use of Gauge datastores since values here are not counters nor rates.

Depending on the values, sometimes I keep the min and max for the day, sometimes I don't.

RRD creation parameters

rrdtool create temperature_in1.rrd --step 300 \

DS:temperature:GAUGE:600:0:U \

RRA:AVERAGE:0.9:1:24 \

RRA:AVERAGE:0.9:6:35064 \

RRA:MIN:0.9:288:1826 \

RRA:AVERAGE:0.9:288:1826 \

RRA:MAX:0.9:288:1826

rrdtool create pressure.rrd --step 300 \

DS:pressure:GAUGE:600:950:1050 \

RRA:AVERAGE:0.9:1:24 \

RRA:AVERAGE:0.9:6:35064 \

RRA:AVERAGE:0.9:288:1826

rrdtool create humidity_in1.rrd --step 300 \

DS:humidity:GAUGE:600:0:100 \

RRA:AVERAGE:0.9:1:24 \

RRA:AVERAGE:0.9:6:35064 \

RRA:MIN:0.9:288:1826 \

RRA:AVERAGE:0.9:288:1826 \

RRA:MAX:0.9:288:1826

rrdtool create light_level.rrd --step 300 \

DS:light_level:GAUGE:600:0:U \

RRA:AVERAGE:0.9:1:24 \

RRA:AVERAGE:0.9:6:35064 \

RRA:AVERAGE:0.9:288:1826

rrdtool create nitrogen_dioxide.rrd --step 300 \

DS:no2:GAUGE:600:0:U \

RRA:AVERAGE:0.9:1:24 \

RRA:AVERAGE:0.9:6:35064 \

RRA:AVERAGE:0.9:288:1826

rrdtool create carbon_monoxide.rrd --step 300 \

DS:co:GAUGE:600:0:U \

RRA:AVERAGE:0.9:1:24 \

RRA:AVERAGE:0.9:6:35064 \

RRA:AVERAGE:0.9:288:1826

rrdtool create noise.rrd --step 300 \

DS:noise:GAUGE:600:0:U \

RRA:AVERAGE:0.9:1:24 \

RRA:AVERAGE:0.9:6:35064 \

RRA:AVERAGE:0.9:288:1826

Having set up a sensor for both gas and electricity, the next step for me was to store the data.

There are countless solutions available for this either local or remote ("in the Cloud").

Probably the most famous one is Xively (which used to be COSM and before that Pachube). Trouble is they went really commercial without any offers for small projects. I tried a few alternatives but decided that I didn't want to publish my data and therefore turned to a local solution.

There are loads of possibilities for data storage, from the classical SQL solutions (MySQL, SQLite, ...), NOSQL solutions. A system which is gaining popularity is Graphite and its Whisper database. In the end, I decided to go for the simplest and probably most used database in the world of monitoring: RRD.

RRD

Almost all opensource monitoring and reporting tools on this planet use RRD. It has a big avantage, the database never ever grows! You lose the details (and even the data) over time but with the right setting this wasn't an issue.

For me, its biggest drawback is that (except with Datastores as 'Gauge') EVERYTHING IS A RATE PER SECOND.

Some calculation is necessary first to convert the pulses into actual usage, then into a rate and when displaying into a meaningfull usage figure.

Gas

Counting

1 pulse = 10 dm3 = 10 litres

Easy... Well how do I store this?

First let's chop the time into 5 minute slots (this the usual base for RRD BTW) and let's count the pulses within a slot. At the end of the slot, one can push the number of litres:

rrdtool update gas.rrd 1407153600:100

Displaying

Internally, RRD will not store the value 100 but 0.3333333333 because it is 100 per 5 min or 100 per 300 sec.

When consolidating (to a 30 min = 1800 sec period), RRD will average all the rates.

If I want to display the gas usage over a given period (5 min, 30 min, 1 day), I then need to multiply the value returned by the length of this period. Resp. 300, 1800, *86400.

A lot of people convert the values into Watt-Hour. Unfortunately the conversion is NOT straightforward and depends on a Correction Factor you can only discover a posteriori on your bill or if lucky on your provider website like this one. Cubic meters are OK for me.

- Power (rate): litre/s

- Energy: m3 per period

Electricity

Counting

1 pulse = 1 rotation = 3.6 Wh

Like for Gas, we slice the time into the same 5 minutes slots and count the pulses within a slot. But remember that RRD stores rates per seconds. So to make sense we have to convert the Watt-Hour in Watt-Second:

1 Wh = 3600 Ws

3.6 Wh = 12960 Ws

Hence 1 rotation of the disk equals 12960 Ws. RRD will automatically store the value in Watts!

Displaying

- Power: Watt

- Energy: Wh for display per period

RRA

As mentioned before, RRD stores the data in a way which means the values will be aggregated over time and you'll loose the original individual values. After thinking a lot about what to do and how to handle it, I settled for the following pattern:

- Step = 5 min = 300 sec (default anyway)

- Base RRA (storing Primary Data Points ):

- 2 hours => 24 rows

- Mainly for debugging and for "realtime" view

- 1/2 hour resolution:

- 2 years = 2 * 365 * 24 * 2 => 35064 rows

- Main view

- 1 day resolution:

- 5 years => 1826 rows

- Archiving as well as daily summary

RRD creation parameters

rrdtool create gas.rrd --step 300 \

DS:gas_usage:ABSOLUTE:600:0:U \

RRA:AVERAGE:0.9:1:24 \

RRA:AVERAGE:0.9:6:35064 \

RRA:AVERAGE:0.9:288:1826

rrdtool create electricity.rrd --step 300 \

DS:electricity_usage:ABSOLUTE:600:0:U \

RRA:AVERAGE:0.9:1:24 \

RRA:AVERAGE:0.9:6:35064 \

RRA:AVERAGE:0.9:288:1826

Now the gas meter has been connected... would there be any chance to do the same with electricity?

Not easy bordering on impossible

A lot of solutions (specially American & British ones) use current transformers clipped straight on to either the live or neutral wire. These can give real-time and very accurate readings. Trouble is, on french installations, both wires are usually combined together in a outer plastic sheath and in the "worst" case not even visible at any point!

Playing within the fuse box not being a great option the only remaining possibility was to "read" the meter itself.

All modernish counter have at least impulse (usually a LED) output. Some more recent even have a "teleinformation" serial communication system, not even talking about the latest generation of smart meter with a USB port).

Mine is a very old rotating disk without any kind of bells and wistles... in short the worst case scenario.

After a bit of research I found what could potentially be the needed part: Fludia FM250. Unfortunately it doesn't seem to exist anywhere else.

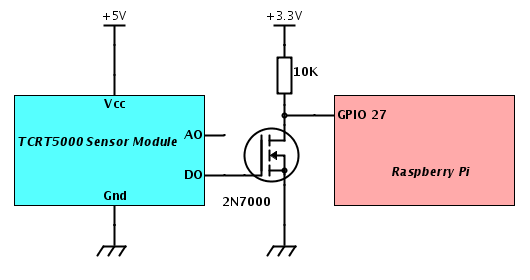

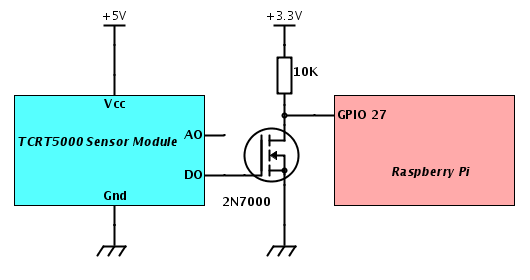

Knowning that my meter could be upgraded at anytime by the electricity provider, I wanted to stay on a cheap and low key solution. Some people on Jeelabs forums mentioned the TCRT5000 also saying that they didn't have much luck!

But googling this reference leads to IR Sensor TCRT5000 for Arduino as well as a TCRT - Infra Red reflectivity sensor + break out board from Ciseco which mention on their website "Revolving or tumblimg numbered Electricity meters".

Having found a "Infra-red reflective distance sensor Module tracing line" (basically a TCRT5000 + LM393) on eBay for a grand total of 6€, I decided to give it a go.

Never give-up!

To cut the story short... it works! I tried first in 5V then in 3.3V and in both case the black line could be detected but...

- The alignment with the wheel is a real pain

- Hooking physically the circuit on the meter box is also a real pain

- Tuning the detection level is tricky

The temporary setup (made of cardboard and sellotape/scotch tape) has been in place for quite a while but I will need to find a better system before the next meter reading by the company.

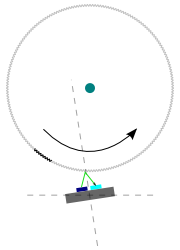

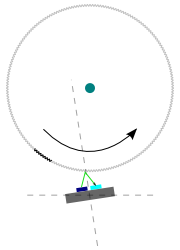

It is worth mentioning that the detection is better (or simply working) when the sensor is installed at an angle as illustrated below.

Crashing

I noticed that sometimes the LM393 (part of the module) crashed and stopped detecting the black zone. It seems that the component doesn't like having its output forced to a voltage. When the Raspberry Pi boots, there is no garantee that the GPIO will be in INPUT mode and voltage free. So, to separate the two, I inserted a transistor (a 2N7000 I had in stock but it should be similar with a NPN). Moreover, it gives the possibility of using 5V for the sensor as if 3.3V should work, in practice it is relatively unstable.

And counting...

The counting set-up on the Raspberry Pi is the same as the gas one. That said, there is also a form of bounce (not mechanical but the result is the same) and so far I haven't managed to completely get rid of it, specially when there are bogus pulses a few seconds apart. I capped (like for the gas) the delay between pulses but this potentially means that I loose accuracy when the disk is spinning very fast.

So accuracy might not be that great but so far it still gives a pretty good picture of the electricity usage and with such a cheap design, it doesn't really bother me.

Schematic

⇇

«

Page 11 / 12

»

⇉